Graining for Plastic Injection Tools

Lumos Laser's GHz burst femtosecond laser technology sets a new standard in plastic injection mold graining. This process not only enhances the aesthetics of the final product but also adds functional characteristics that are highly sought after in the industry.

Key Benefits and Applications:

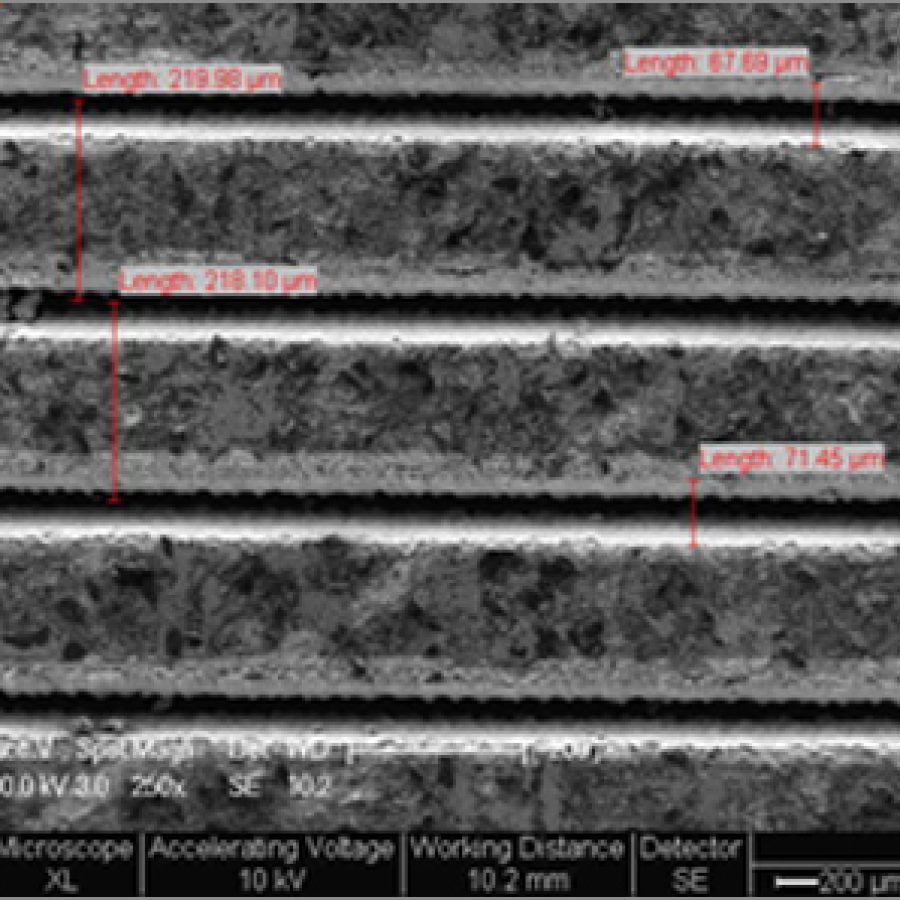

- Precision and Detail: Achieves fine, intricate grain patterns with unparalleled detail, essential for both visual appeal and texture functionality.

- Consistency and Quality: Uniform texture application ensures each product maintains the highest quality, reflecting well on mass production consistency.

- Speed and Efficiency: Reduces turnaround times significantly, streamlining the production process while maintaining high-quality texturing.

- Material Preservation: The cold-ablation process minimizes thermal impacts, preserving mold material and extending mold lifespan.

- Versatility in Texturing: Capable of creating a range of textures on various mold materials, from hardened steels to sensitive alloys.

- Soft Touch Textures: Produces a luxurious feel for consumer electronics, automotive interiors, and household items.

- Hydrophobic/Hydrophilic Surfaces: Enables water-repellent or water-attractive features for advanced fluid management in medical devices and more.

- Anti-Glare Finishes: Ideal for electronic displays, automotive components, and other surfaces where glare reduction is paramount.

- Aesthetic and Custom Patterns: Offers customizable designs for product differentiation and enhanced consumer appeal.

With Lumos’s GHz burst femtosecond lasers, the potential for innovation in mold texturing is vast, allowing for the production of plastics with advanced features like hydrophobicity, hydrophilicity, and soft-touch, as well as unique, consumer-centric designs.

- Wu, P. H., et al. “Fabrication of large-area hydrophobic surfaces with femtosecond-laser-structured molds.” Journal of Micromechanics and Microengineering 21.11 (2011): 115032.

- Lee, Chia-Yu, et al. “Using femtosecond laser to fabricate highly precise interior three-dimensional microstructures in polymeric flow chip.” Biomicrofluidics 4.4 (2010).

- Conrad, Daniel, and Lars Richter. “Ultra-short pulse laser structuring of molding tools.” Physics Procedia 56 (2014): 1041-1046.