Coating Removal over Glass

GHz Burst Femtosecond laser technology is advancing photovoltaic manufacturing through precise selective ablation, optimizing the efficiency of solar cells. This technology is crucial for the P1, P2, and P3 patterning steps that are integral to forming the electrical interconnections in thin-film solar cells.

Key Benefits:

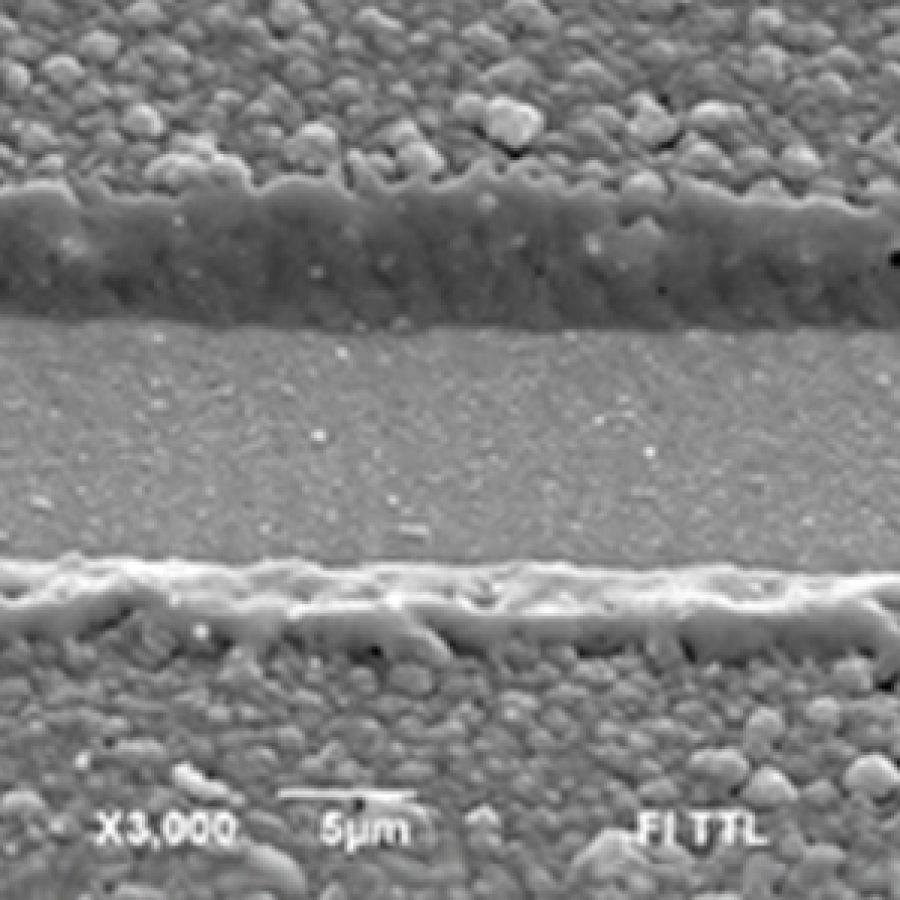

- Precision Patterning: Delivers accurate ablation for the P1, P2, and P3 processes, essential for structuring the front contact, intrinsic layers, and back contact without damaging underlying layers.

- Enhanced Throughput: The GHz burst capability increases processing speeds, enabling high-volume production while maintaining exacting standards.

- Minimal Thermal Stress: The femtosecond pulses reduce thermal effects, safeguarding the photovoltaic material’s functionality and efficiency.

- Material Versatility: Effectively processes a range of thin-film technologies, such as CdTe, CIGS, and amorphous silicon.

Applications:

- Anti-Reflective Coating Structuring: Improves light absorption and reduces reflection losses.

- Contact Opening on Thin-Film Cells: Precisely removes layers to expose underlying contacts without damage.

- Edge Isolation: Prevents electrical leakage and enhances cell efficiency by isolating the edges of silicon wafers.

Lumos Laser’s GHz burst femtosecond lasers are not only enhancing the precision in photovoltaic production but also enabling a more efficient, cleaner energy generation, leading the way towards a greener future.

- Hermann, Jea, et al. “Selective ablation of thin films with short and ultrashort laser pulses.” Applied Surface Science 252.13 (2006): 4814-4818.

- Račiukaitis, G., et al. “Selective Ablation of Thin Films with Picosecond‐Pulsed Lasers for Solar Cells.” AIP Conference Proceedings. Vol. 1278. No. 1. American Institute of Physics, 2010.

- Krause, S., et al. “Precise microstructuring of indium-tin oxide thin films on glass by selective femtosecond laser ablation.” EPJ Photovoltaics 4 (2013): 40601.