GHz Burst Laser Technology

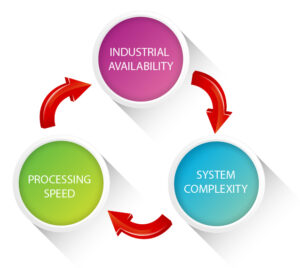

Lumos Laser's pioneering GHz Burst Technology is becoming an innovation to make femtosecond lasers industrially available. Utilizing this technology we micromachine materials faster, with exceptional precision, using less energy and still preserve the integrity of the machined surface.

Previous slide

Next slide

The GHz Burst Technology

The GHz Burst technology enables a new state of material removal called ‘ablation cooling’ by creating extremely high repetition rates. This technology brings following advantages:

![]() High material removal speed with low-power laser architecture

High material removal speed with low-power laser architecture